English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

Heavy duty precise grinding machine veneer knife grinder

You can rest assured to buy high quality Heavy duty precise grinding machine veneer knife grinder with cheap price from Packer.Heavy duty precise grinding machine veneer knife grinder

Send Inquiry

Product Description

Buy Heavy duty precise grinding machine veneer knife grinder In Stock

Introduction of Heavy duty precise grinding machine veneer knife grinder

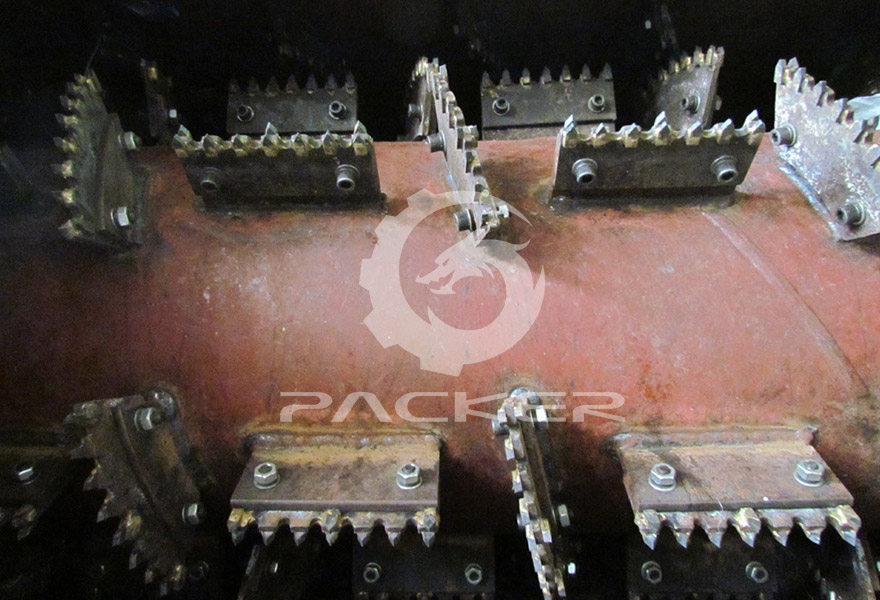

PACKER® Heavy duty precise grinding machine veneer knife grinder is for grinding used blades to be sharped. And can use again.

We provide fantastic power in high-quality and development,merchandising,profits and marketing and advertising and operation forHeavy duty precise grinding machine veneer knife grinder, We, with open up arms, invite all intrigued prospective buyers to visit our web page or get in touch with us specifically for additional info.

2019 China New Design China Plastic Auxuliary Machine, Plastic Crusher, We now have our own registered brand and our company is developing rapidly owing to high quality goods, competitive price and excellent service. We sincerely hope to establish business relations with more friends from home and abroad in the near future. We look forward to your correspondence. We are trading company and manufacturer for PACKER®Heavy duty precise grinding machine veneer knife grinder.Plastic recycling machines, Plastic injection machine, Mold blowing machine, Mask making machine and so on. We have professional technical team for technical support and service.

A heavy-duty precision grinding machine for veneer knife grinding is a specialized piece of equipment used to sharpen and grind veneer knives with high precision. Veneer knives are used in the woodworking industry for cutting thin sheets of veneer from logs or for slicing veneer from flitches. These knives need to be sharpened accurately to ensure smooth and clean cuts. The heavy-duty design of the grinder allows for consistent and precise sharpening of these specialized knives.

Here's an overview of how a heavy-duty precision grinding machine for veneer knife grinding works and its benefits for maintaining accurate and sharp veneer knife edges:

Knife Mounting: The veneer knife to be sharpened is securely mounted onto the machine's fixture or holder. Some machines might have specialized fixtures that ensure proper alignment and stability during the grinding process.

Grinding Wheel: The grinder is equipped with a grinding wheel specifically designed for precision sharpening. The wheel is made of abrasive materials and rotates at high speed to remove material from the knife's edge.

Adjustment: The machine allows for precise adjustment of the sharpening angle and bevel of the veneer knife edge. This adjustment ensures that the knife is sharpened at the correct angle for optimal cutting performance.

Grinding Process: As the veneer knife's edge comes into contact with the rotating grinding wheel, the abrasive action of the wheel removes material from the edge, effectively sharpening it. The machine's design ensures consistent and controlled material removal.

Cooling and Lubrication: To prevent overheating and maintain the sharpness of the grinding wheel, coolant or lubricating fluid is often applied during the grinding process. This ensures that the heat generated does not affect the temper of the knife's edge.

Precision and Accuracy: Precision grinding machines for veneer knife grinding often come equipped with advanced features for precise adjustments, fine-tuning, and monitoring of the sharpening process. Digital displays and controls enable operators to achieve the desired level of sharpness and edge quality.

Honing (Optional): Some machines offer the option of honing after the initial grinding. Honing involves using a fine-grit abrasive process to further refine and polish the knife edge for an even smoother cutting performance.

Quality Control: The accuracy and precision offered by these grinding machines result in consistent and high-quality sharpening results. This is crucial for maintaining the cutting performance of veneer knives.

Benefits of a Heavy-Duty Precision Grinding Machine for Veneer Knife Grinding:Specialized Sharpening: These machines are designed specifically for veneer knife sharpening, ensuring accurate and efficient results.Consistency: The machine's design ensures uniform material removal, resulting in consistent sharpening across the entire knife edge.Time Efficiency: Precision grinding machines offer quick and efficient results, reducing downtime for tools.Longevity: Properly sharpened veneer knives perform better and have a longer lifespan, reducing the need for frequent replacements.Customization: The ability to adjust sharpening angles and bevels allows for customization based on the veneer knife's application.Overall, a heavy-duty precision grinding machine for veneer knife grinding is an essential tool for the woodworking industry, ensuring the quality and accuracy of veneer cutting processes. It helps maintain the performance and efficiency of veneer knives, contributing to improved product quality and production processes.

These pictures can better help you understand PACKER® Heavy duty precise grinding machine veneer knife grinder

RUGAO PACKER MACHINERY CO.,LTD. is Heavy duty precise grinding machine veneer knife grinder manufacturers and suppliers in China who can wholesale Heavy duty precise grinding machine veneer knife grinder. We can provide professional service and better price for you. If you interested in Heavy duty precise grinding machine veneer knife grinder products, please contact with us. We follow the quality of rest assured that the price of conscience, dedicated service.

Company

RUGAO PACKER MACHINERY CO.,LTD was built in 2015. We are trading company and manufacturer for Heavy duty precise grinding machine veneer knife grinder .Plastic recycling machines, Mask making machine and so on. We have professional technical team for technical support and service.

Deliver,Shipping And Serving

Delivery: 30 days after getting the payment.

Shipping: By sea

Service: 1 year guarantee. After guarantee. We will keep all parts as cost price for our customers. And service for all life.

Servicing:

Professional technical team for offering our customers professional suggestions. To get most reasonable technical for the production line.

Sales will follow the order and report to customer the production real situation every one week.

24 hours online-service and help customers to solve problems asap. Offer all necessary documents and manual book to customers for helping to installation Heavy duty precise grinding machine veneer knife grinder. We also offer technical to be at customer factory for installation and testing. Service whole life for our customers.