English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

Waste Film Fiber Granulator Recycling Plastic Agglomerator

Customized China high quality PACKER® Waste Film Fiber Granulator Recycling Plastic Agglomerator is for making plastic films into particle. It can used for films. Fiber. Nylon and so on(Raw Material wall thickness needs to be less than 2mm). The final product from agglomerator can use in plastic granulating line directly. And this can improve the granulating line capacity because particle will be more easily to feed into granulating line.

Send Inquiry

Product Description

A waste film fiber granulator and plastic agglomerator are two separate pieces of equipment used in the plastic recycling industry to process and recycle plastic waste, such as film, fibers, and other plastic materials. Let's look at each of these machines individually:

Waste Film Fiber Granulator:

A waste film fiber granulator, also known as a plastic granulator or pelletizer, is a machine used to process plastic waste into small pellets or granules. These granules can be easily melted and reshaped into new plastic products. Here's how the process typically works:Material Feeding: Plastic waste materials such as films, fibers, or other forms are fed into the granulator.Cutting and Size Reduction: Inside the granulator, rotating blades or knives cut and shred the plastic waste into smaller pieces.Heating and Extrusion (Optional): Some granulators have the capability to heat the plastic material and extrude it through a die, creating uniform plastic pellets or granules.Cooling and Collection: The newly formed plastic granules are cooled and collected for further processing or storage.The resulting plastic granules can then be used as raw material in various manufacturing processes to create new plastic products. Plastic Agglomerator:

A plastic agglomerator is a machine used to process and recycle plastic materials by agglomerating, densifying, and pre-processing them before granulation. Here's how the process typically works:Material Feeding: Plastic waste, including films, fibers, or other forms, is fed into the agglomerator.Heating and Agglomeration: The agglomerator uses heat and mechanical action, such as rotating paddles or blades, to soften and agglomerate the plastic materials into larger chunks or masses.Cooling and Cutting: After agglomeration, the plastic mass is cooled and cut into smaller pieces or pellets.Granulation (Optional): The agglomerated plastic can then be further processed in a granulator to produce uniform plastic pellets or granules.Both the waste film fiber granulator and plastic agglomerator play essential roles in the plastic recycling process by converting plastic waste into a form that can be easily processed and reused. These machines contribute to reducing the environmental impact of plastic waste and promoting a more sustainable approach to plastic consumption and disposal.

Waste Film Fiber Granulator Recycling Plastic Agglomerator of features:

Capacity: 100-1000kg/h

Automatic discharging.

Double bearing for holding the main shaft.

Water flushing automatic

Easy to clean and maintenance

Specification of Waste Film Fiber Granulator Recycling Plastic Agglomerator

| Plastic Films Agglomerator | |||||

| Model | Volume(L) | Effective volume(L) | Main shaft speed(rpm) | Motor power | Heating type |

| RGP-100 | 100 | 75 | 800 | 37 | Friction by itself |

| RGP-200 | 200 | 150 | 800 | 55 | Friction by itself |

| RGP-300 | 300 | 225 | 800 | 75 | Friction by itself |

| RGP-500 | 500 | 375 | 750 | 90 | Friction by itself |

| RGP-800 | 800 | 600 | 750 | 110 | Friction by itself |

Details

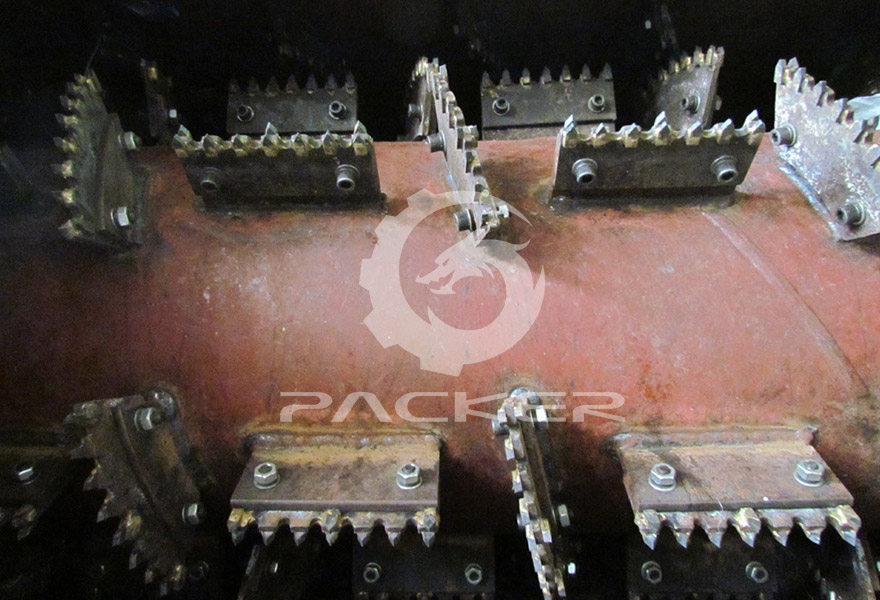

These pictures can better help you understand PACKER® Plastic Films Agglomerator

5.Company

RUGAO PACKER MACHINERY CO.,LTD was built in 2015. We are trading company and manufacturer for Plastic Films Agglomerator .Plastic recycling machines, Mask making machine and so on. We have professional technical team for technical support and service.

6.Deliver,Shipping And Serving

Delivery: 30 days after getting the payment.

Shipping: By sea

Service: 1 year guarantee. After guarantee. We will keep all parts as cost price for our customers. And service for all life.

Servicing:

1.Professional technical team for offering our customers professional suggestions. To get most reasonable technical for the production line.

2.Sales will follow the order and report to customer the production real situation every one week.

24 hours online-service and help customers to solve problems asap. Offer all necessary documents and manual book to customers for helping to installation Plastic Films Agglomerator. We also offer technical to be at customer factory for installation and testing. Service whole life for our customers.